Dutton Kit Cars and their owners

So, collected last weekend and the first chance I get to go over it we have snow / hail / rain and gales... lovely if your a penguin I guess...

Q835XSC purchased from the factory in 1988, completed in 1990, stored for the winter in 1991 and there it sat for 22 years, possibly one of the saddest Legerras I have ever seen apart from my black one.

It was rough, body panels off, windscreen missing and a sorry case of 4 wheel drum brakes...

Today it got a wash, nothing special just caravan cleaner and a sponge but an improvement on fungus and moss...

Hell of a job on here lads, starting with a body off chassis check, bushes and bolts and some refurb bits fresh from the sand blasting cabinet.

I will be posting more detail on Mr G's but major updates will be copied onto here too.

Add a Comment

-

Comment by Brian (up north) Morris on March 3, 2016 at 19:10

-

HELLO you div from darn sarf i mean you -)

-

Comment by Brian (up north) Morris on March 3, 2016 at 18:47

-

wow was not expecting to see it so shiny good stuff ade

-

Comment by Adrian Southgate on March 3, 2016 at 18:30

-

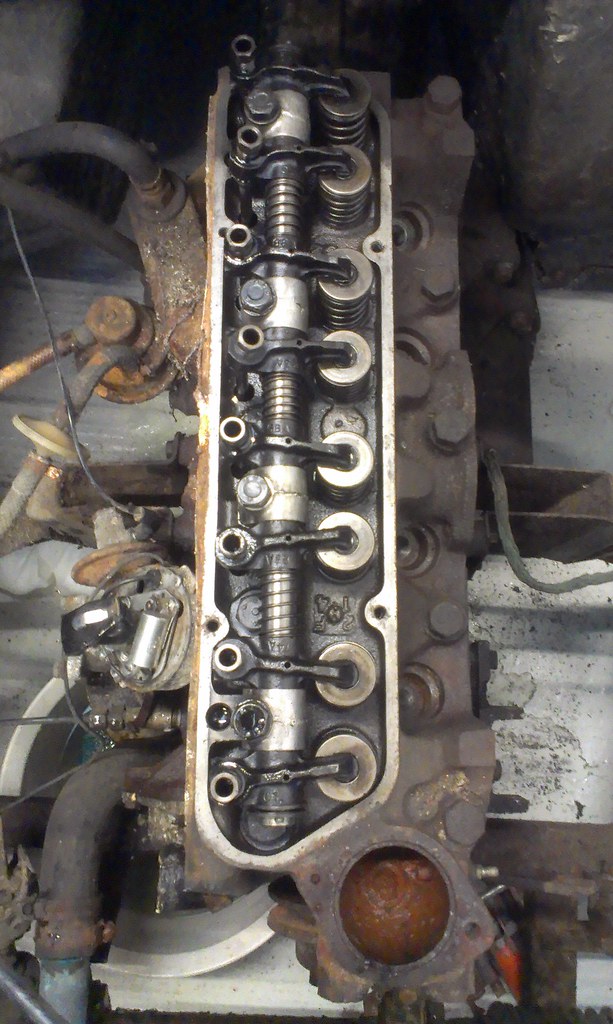

Tinkering... Started taking bits off the parts car to make ready for the body off part. Decided to strip the engine in the bay. Got the manifolds off and took the rocker cover off too... pulled the new (!) plugs and dropped a liberal squirt of WD down each bore.. Waterways were a bit blocked with whitish gak but i've seen worse.

This is not optimistic as the rocker cover is shot, very corroded as it the rest of the stuff in the engine bay.

Fortunately it would appear that this engine hasn't been run... this was the inside...

Encouraged by this I took the big bar and stuck a socket on the crank bolt... expecting it to be a massive effort, skinned knuckles, socket flying off the bolt etc... and it just turned, nearly dropped the bar in shock.

I didn't move it far, just a few degrees to make sure the valves were moving then stopped. Head off next to see what damage has been done to the bores by standing for donkeys years. I'm a lot more optimistic now about this engine than I was at lunchtime.

-

Comment by Steve Kerswell on February 28, 2016 at 15:10

-

Over slots use specific washers, normal washer will collapse into the slot. Longer bolts with spring washers were allowed in specific applications.

-

Comment by Paul Sheridan on February 28, 2016 at 14:37

-

Only need a washer where there is a slot or where you don't want something that's being clamped to turn during tightening. ....... Technically speaking ;-))

-

Comment by Adrian Southgate on February 28, 2016 at 13:58

-

@ Daryl, will do mate. He's a good chap and very helpful too.

@ Steve, it mystifies me why you wouldn't fit washers. None of the leggie's bolts have them, bad engineering.

-

Comment by Steve Kerswell on February 28, 2016 at 10:55

-

Not telling you to suck eggs, bolt, washer, washer, nyloc. If the inspectors were OK they would allow four threads. But if they were on a jobs worth, two full threads. Spent a fair bit of my younger days changing bolts to comply. Just as long cutting them to length and filing the burrs.

-

Comment by Adrian Southgate on February 28, 2016 at 9:36

-

Cheers Boys, I was planning to reduce the length of the bolts anyway as they are a little long but having an accurate target is always good.

Ian, who runs IFS, is DOC friendly and has a huge selection.

-

Comment by Steve Kerswell on February 28, 2016 at 9:20

-

Just ensure the length is correct, 4threads maximum through a nyloc is the standard, any more and the nyloc is threaded, hence useless.

-

Comment by Dave Adams on February 28, 2016 at 7:29

-

my local bolt supplier still has imperial bolts and nuts......they are usually 3/8" UNF on Duttons very close to 10mm....so folks drill them out.....this has two effects...it makes the brackets useless for further use with the right bolts, and it knackers the bushes as the heat from drilling often unbonds the steel sleeve. Bracket placement on Dutton chassis often seems a little errr.....close enough will do.

© 2025 Created by Tim Walker (The Bodger).

Powered by

![]()

You need to be a member of DuttonOwners to add comments!

Join DuttonOwners